For some modelers, the search for the perfect nipper is an endless endeavor .... that magic tool that would reduce this sprue to a batch of perfectly trimmed parts ... and while it will provide you with a lifelong activity, it’s not going to get that model built. The fact is, no nipper or sprue cutter is really able to get you to the nirvana of an always perfectly trimmed part. We have to recognize that we’re really at the mercy of the mold designers and the technology available to a particular model manufacturer. Unless the attachment between the part and the sprue, or gate, is designed in a conscientious manner, you’re going to need to some spend some quality time with a blade, file, or abrasive. However on those occasions when the stars align perfectly, a good pair of plastic nippers can make removing a part off the sprue a much more pleasant experience.

As designs go, there are two basic forms of construction, stamped sheet metal with a rivet type joint and forged with an overlapped type joint. While I’ve bought and tested a number of so-called “quality” stamped sheet metal rivet types, I’ve never found a pair that even came close to the performance of a well made forged type. The joints have always been sloppy so the jaws don’t close reliably and the metal has generally been softer so they easily nick ... even the one that was supposed to be for cutting rail, so I have to say, on my bench, these are useless because there are much better alternatives.

However, like anything, quality varies from manufacturer to manufacturer, and just because it’s forged doesn’t mean that it’s great. But before I get into the specifics, I want to distinguish between sprue cutters and nippers, because we generally use these terms interchangeably ... but there’s one very significant difference ... size. Sprue cutters are larger and able to easily cut through the actual sprue or runner without being damaged. Most of the small cutters that we like to use for trimming off small parts are not as stout ... with the smallest of these types having warnings against damage if used on too thick of a material. If you find yourself needing to cut thicker plastic, you would be wise to purchase something larger and more functional.

First up is the Tamiya 74001 all around side cutter ... it is the most stout of all the nippers that I’m showing ... and more capable of cutting through surrounding sprue material ... but again ... if your cutting through the big stuff .... reach for a larger pair of sprue cutters .... both jaws are relatively thick but sharp enough to do a surprisingly good job ... they have a slight curve from side to side so you can get them in close ... if I could only have one pair in my kit ... these would be the ones.

The Tamiya 74035 is a bit smaller than the 74001 and the jaws are thinner ... they curve from side to side ... but are flat from top to bottom and thinner than the 74001 ... so if you’re cutting surrounding sprue ... get the material as far as possible into the jaws.

The Tamiya 74123 is a completely different animal ... you can tell by the construction that these are made to a different standard ...more like a quality jewelers tool ... the jaws are much thinner and have a long taper that lets them get into spots that none of the other nippers do ... the outside surface has a slight curve from side to side ... these are not for cutting heavy material ... but if you want a pair of nippers that can get to any part and cut as sharp as all but the GH SPN 120 ... these are the champs.

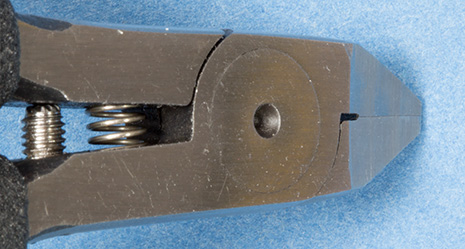

The “God Hand” SPN 120 has sort of become a legend ... it is the sharpest of the bunch ... using a single edge design and an extremely thin ... sharp cutting jaw ... it can leave an extremely smooth cut ... depending on the plastic .... the cutting jaw is very thin and easily damaged so there is a set screw to allow you to adjust the pressure on the blade ... and likewise ... you only use these nippers on appropriate gate attachments at the part ...... while they’re the sharpest of the bunch ... the stubby .. delicate jaws really limit their use ... so you’ll need to have a more durable pair of cutters on your bench for general use.

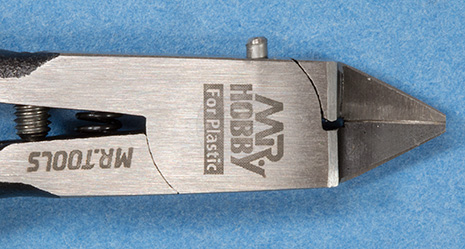

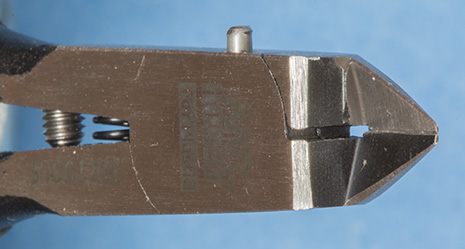

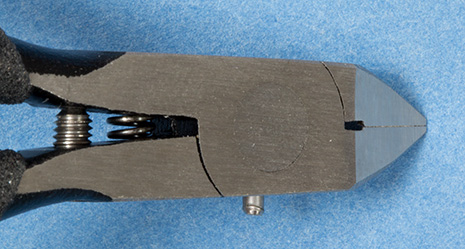

The Mr Hobby MT 103 is a nicely turned out pair of nippers that do a yeoman like job ... nothing spectacular ... but certainly a substantial cut above the stamped scissor types.

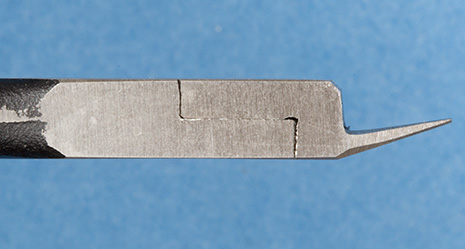

Flush cutting refers to the fact that the outside face is ground so that the jaws meet together to form a flush surface that leaves a relatively straight ... flush cut .... as opposed to a traditional diagonal cutter that leaves a much more pronounced ... pinch cut .... In addition to a flush outside face ... some nippers are made with only one cutting jaw and one flat surface jaw .... the theory here is that ... the cutting blade is supposed to actually cut through the material ... because the flat surface is only stabilizing the material .... as opposed to having both jaws cut which might tend to pinch the material more ... it’s a nice theory ... but I’ve found that in real world use ... both designs leave a pinch.